Gam’inBIZ

Client: Gam’inBIZ

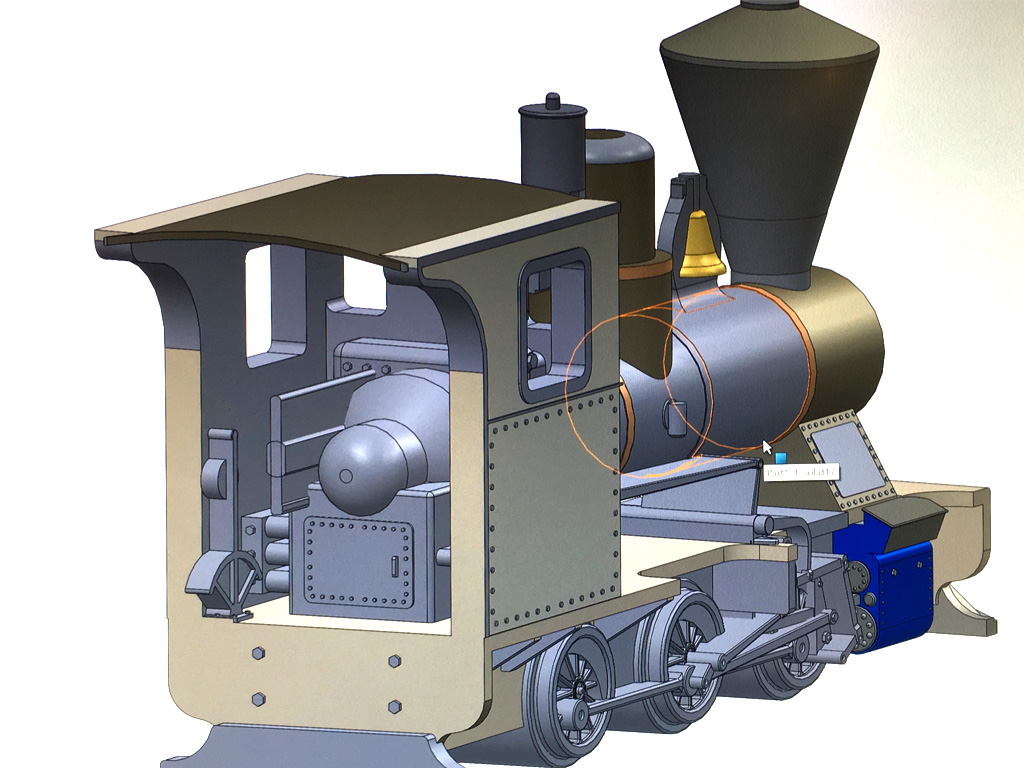

Adjustments 3D design DTR: Ramon Jahn

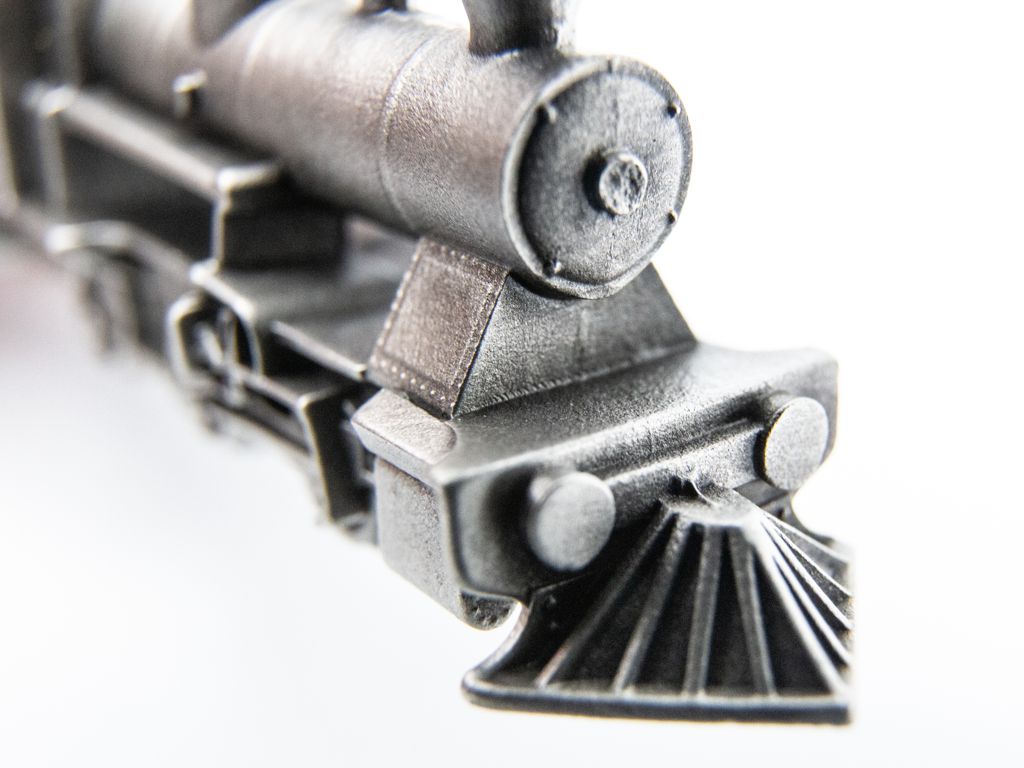

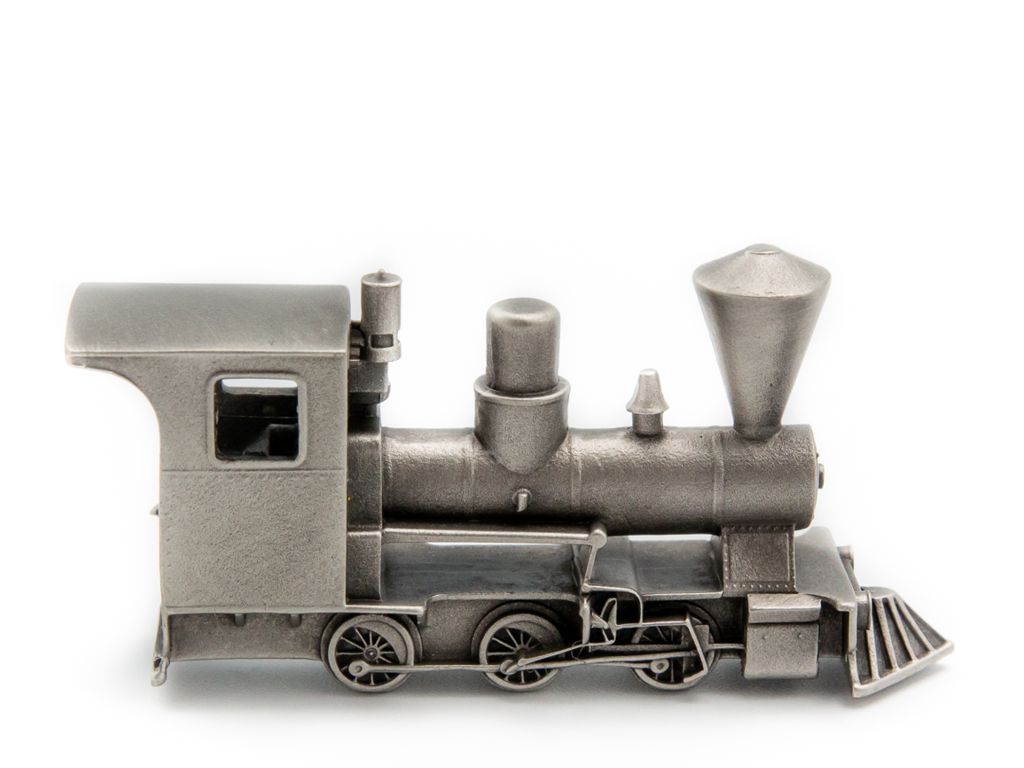

Format: 50 x 25 x 10 mm

Material: tin alloy

Gam’inBIZ

Gam’inBIZ is a small, Dutch board game publisher, based in Nijmegen. The company was founded in 2018 by Michiel de Wit and has since released various games. Games that they invent themselves or that are translated from abroad and thus introduced on the Dutch market. Compact games that do not affect your closet space.

Rollecate

The game Rollecate is about a historic steam locomotive that was built in 1967 by a well-known Dutch engineer. The Nijmegen population will recognize the train as the Goffert train. She has been forced to stand still for the past 5 years and is eager to start rolling again. And the players of this game help her with that!

The game consists of 55 playing cards, 4 modified dice and a wooden train figure.

A pewter train is included with the deluxe edition of the game.

We produce thousands of miniatures for table top games!

Looking for a producer for your pewter or thermoplastic resin game miniatures?

De Tinnen Roos thinks along with you in the development of your game. From 3D design to production.

Please feel free to contact us for the possibilities and a quotation.

Techniques tin Goffert train

Design and model

Design on the computer

Existing 3D drawings were used to design this miniature train. These have been adjusted by us so that the train releases of the mold and the details have enough strength. Adjustments were made by Ramon using SolidWorks.

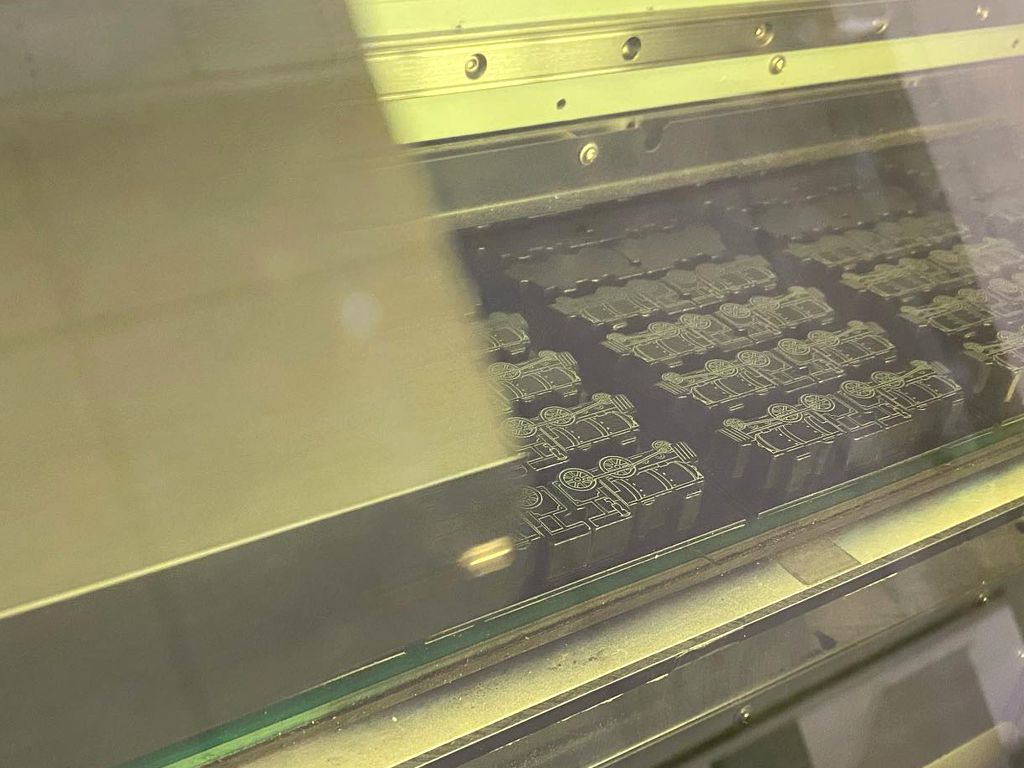

3D printing

We were able to make the completed 3D drawing tangible with the Asiga 3D printer. The parts are built up layer by layer. A frame is printed on the sides of the parts to ensure that the hot mass does not collapse during printing. Before the train can be used, the frame is cut loose and the object is thoroughly cleaned with alcohol.

Casting

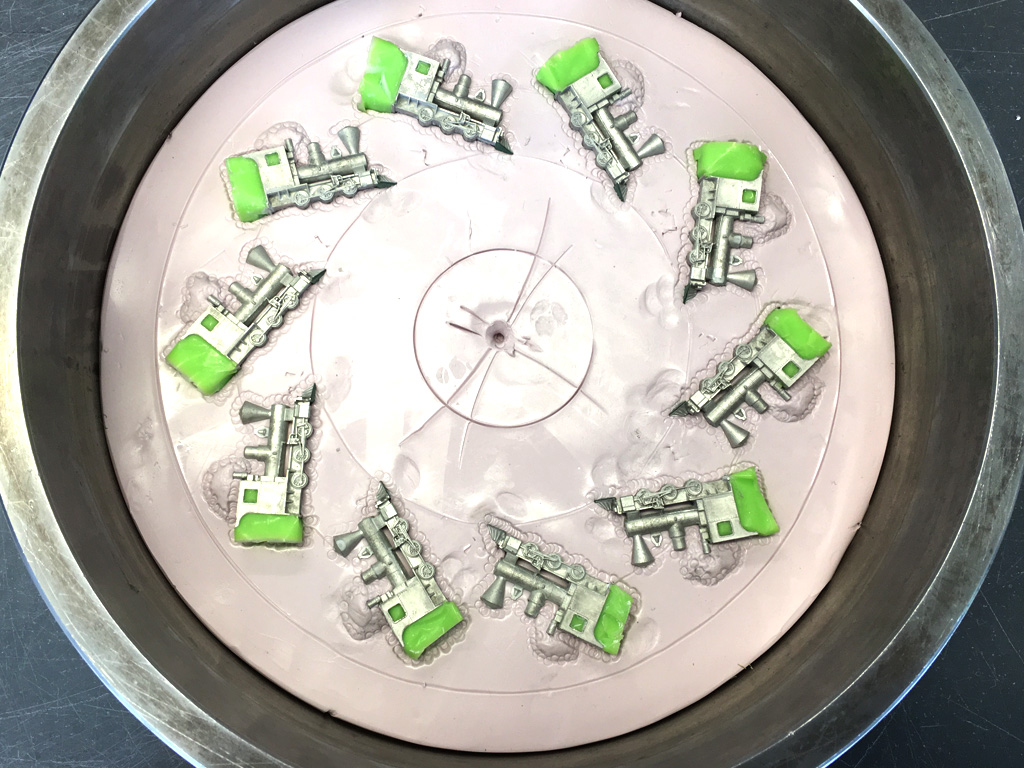

Making mold and casting

A number of masters were cast in a first mold using the plastic print. Masters are used to make the production mold. All molds are manufactured in-house and adapted per product for the best casting results.

Alloy

It is cast with a tin alloy. This alloy is produced by ourselves in the casting pots. With each pour, the mixture is manually poured into the spincasting machine.

Finishing

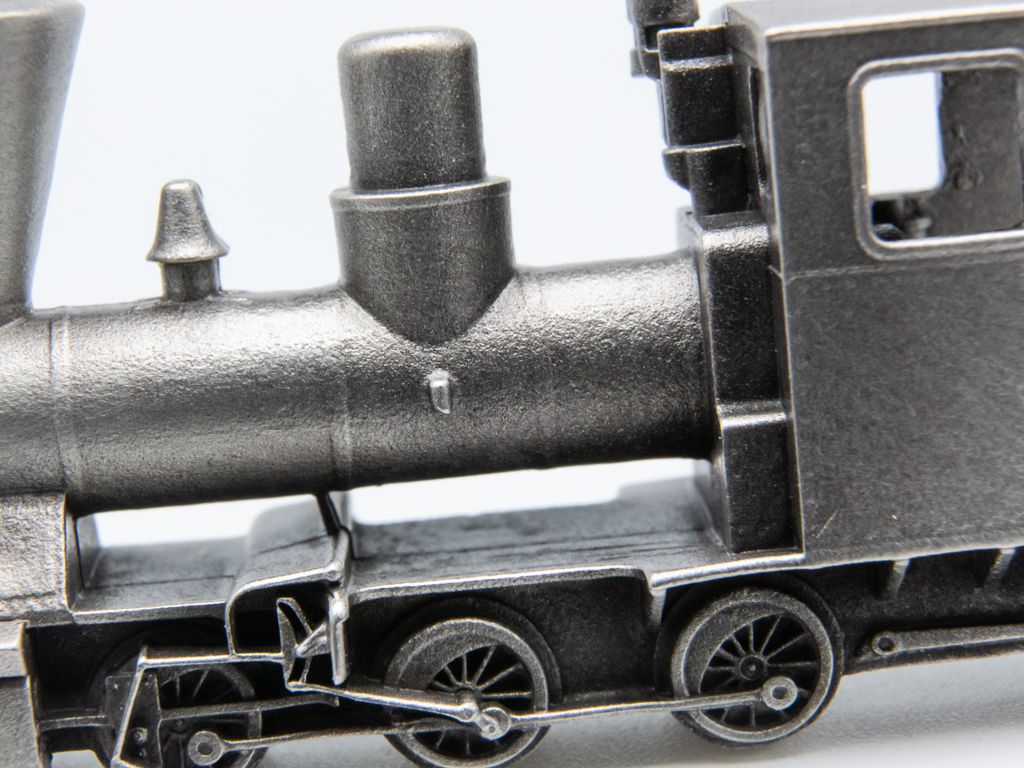

Finishing with acids

After cutting the train clean and grinding the edges, the whole is not yet ready. The dull silver color of the material itself is still present. To get the antique look of our end product, the parts have been given an acid bath. The entire surface was carefully made free of grease and dust before the acid was added. The smallest details were brushed with a toothbrush so that no spots were missed. Finally, the locomotive has been brushed clean to buff away the dark layer and give the miniature artwork its final appearance. A layer of Zapon lacquer ensures that the miniature retains its color and that the acid layer cannot give off color. At the same time it gets a small gloss layer.

Techniques wooden steam train and dice

Design and model

Measure and design

Both the wooden train and the blank dice are semi-finished products that we have received. They have been carefully measured in order to make a good design. The measures have been taken over in a drawing program. A design is then made within the framework of the object that does justice to the game.

Print file

Three different print files have been made for printing an image on the wooden train and the dice. Within the file, the maximum print range of the UV printer is examined. To make the production as high as possible, we create print files in which the object is placed as often as possible. In the case of the dice, one image is printed on several sides and it is sufficient to turn the dice itself over each time. Two files have been created for the train for printing on both sides. This was necessary as the sides are mirrored from each other.

Create a print mold

Placing objects in the UV printer is a precision job. Placing a millimeter skewed can already result in a rejected print. This is exactly the reason why we make molds for large badges. This can be a mold of plywood or plastic. The object to be printed is lasered several times from a plate. This on the basis of the formats in the print file. This template ensures that the objects to be printed are always in the same place.

Printing

With the self-made mold, designs on the trains and dice are printed in the UV printer. This is done per item, and for the trains per side, so that they can be printed one after the other in larger badges. The ink we use has no drying time, so the pieces are immediately usable. It is extra handy that objects can be rotated directly and printing can continue. A big advantage with the dice.