Casting

Expert in details

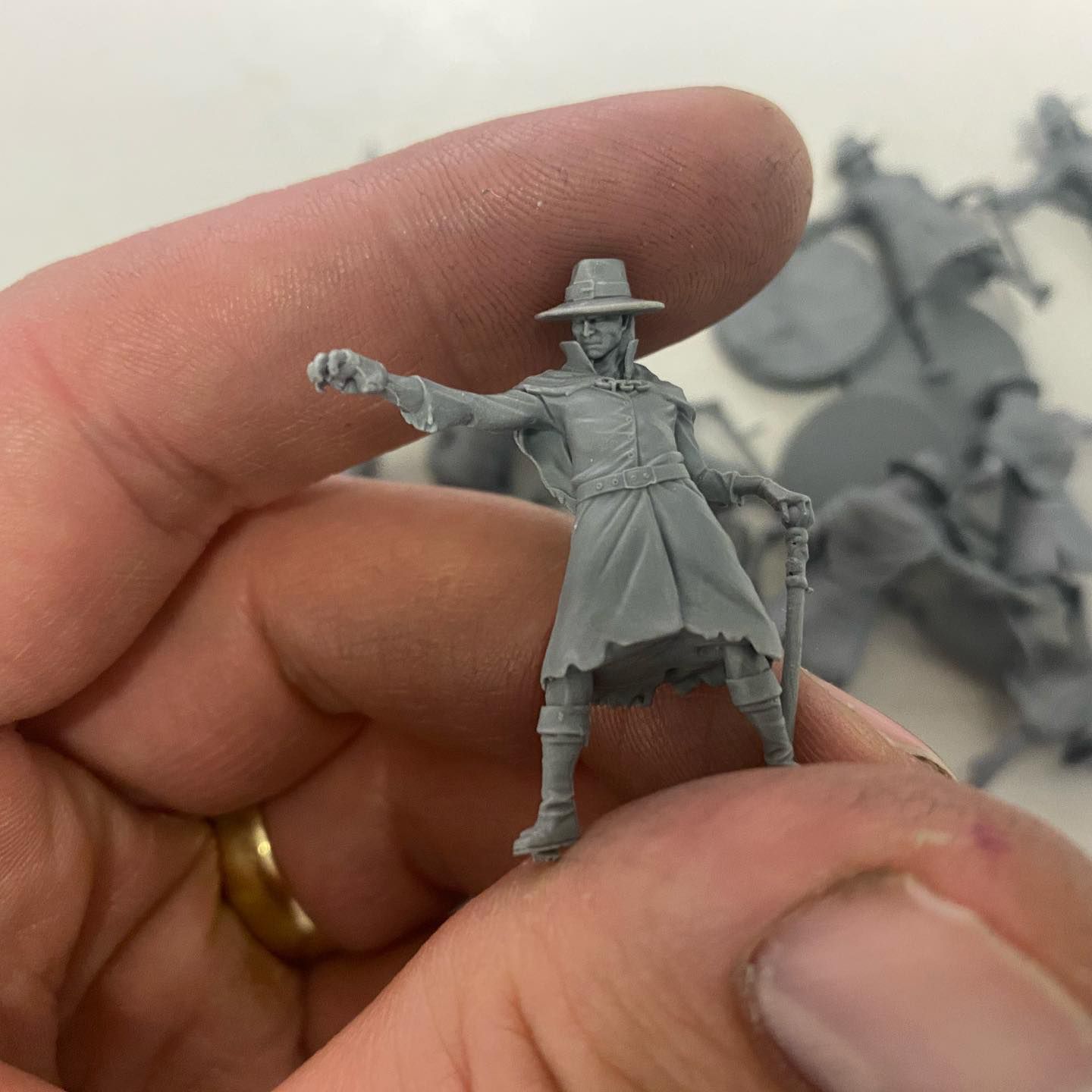

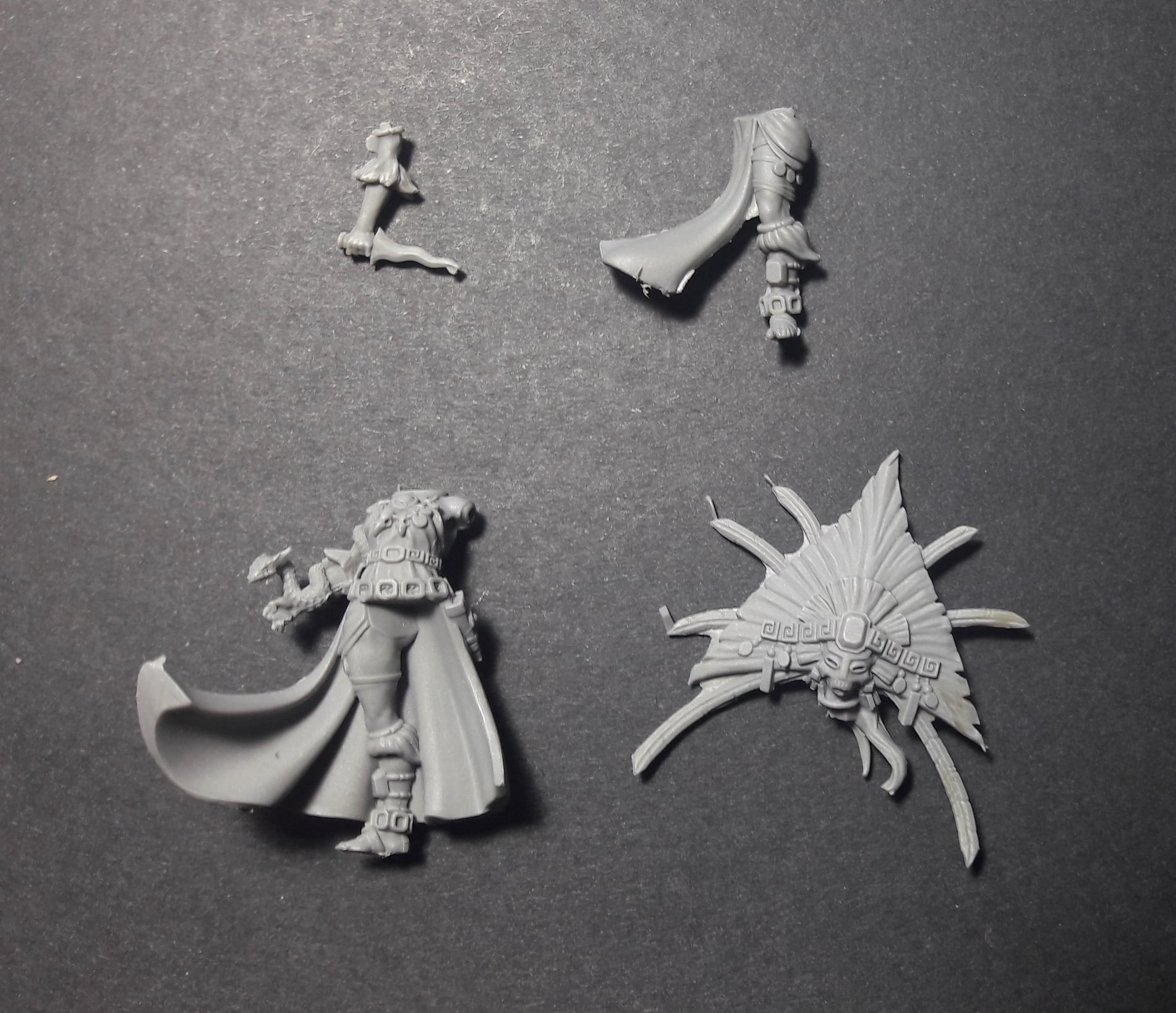

De Tinnen Roos is an expert in making miniatures. We can say this because we control every step of the production process. Thanks to our expertise in making molds, we know exactly how we can get your creation in the mold in the bast way. With every design we do everything we can to achieve the highest possible detail. If you take a closer look at our results, you will discover more and more amazing details.

Small and large productions

Our machines are ready for casting every day. Before the day starts, the pouring kettles already start to heat up so that we can get started immediately upon arrival. This way we get more results from our production day.

You as the client determine the number of copies of your order. We can cast small badges or a large production of several thousand copies.

We cast for…

De Tinnen Roos is a welcome partner for well-known game designers at home and abroad. In addition to renowned companies, we also work together with Kickstarters. In short, we cast for everyone!

Do we also cast for you?

Are you looking for a producer for your casting? Look no further, because we can be of service to you. Together we look at the most suitable casting materials and how your product can be achieved in the best possible way. From design, design control, mold making and casting we come to a final assembly and finish. You determine which steps in the process we take for you. From start to finish, or will we just take a few steps.

Contact us for a no-obligation quotation.

Choosing casting material

Casting in metals

Tin

As a tin foundry, we mostly cast with tin. Both in pure form and in alloys of different percentages. The alloys consist of tin, copper and antimony. By adding copper and antimony to tin, the metal hardens, but still remains flexible. The tin alloys we use are from the PURiTin brand.

Zamac

In addition to tin, we also have the option of working in the somewhat harder zamac (also called zamak). This is an alloy of zinc, aluminum, magnesium and copper. We use Zamac for products that are not allowed to bend, such as keys.

Bismuth

We mainly use bismuth when making masters. It is not flexible, but unfortunately a bit more fragile. It is very suitable as a material for masters, since more pressure is put on an object when making a mold. Small bends and deformations will be visible in every casting. Using a bismuth master ensures a good production mold. Besides the casting of masters, we also use bismuth in the production of coins. The liquid metal fills in the mold faster and comes out just that little bit nicer.

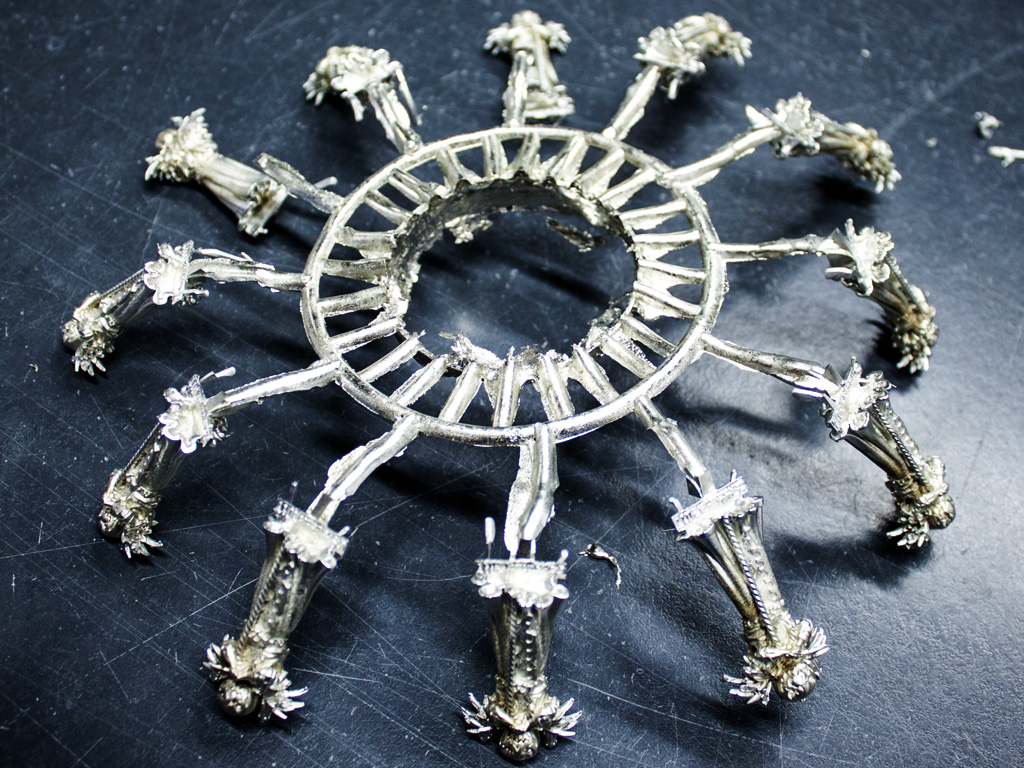

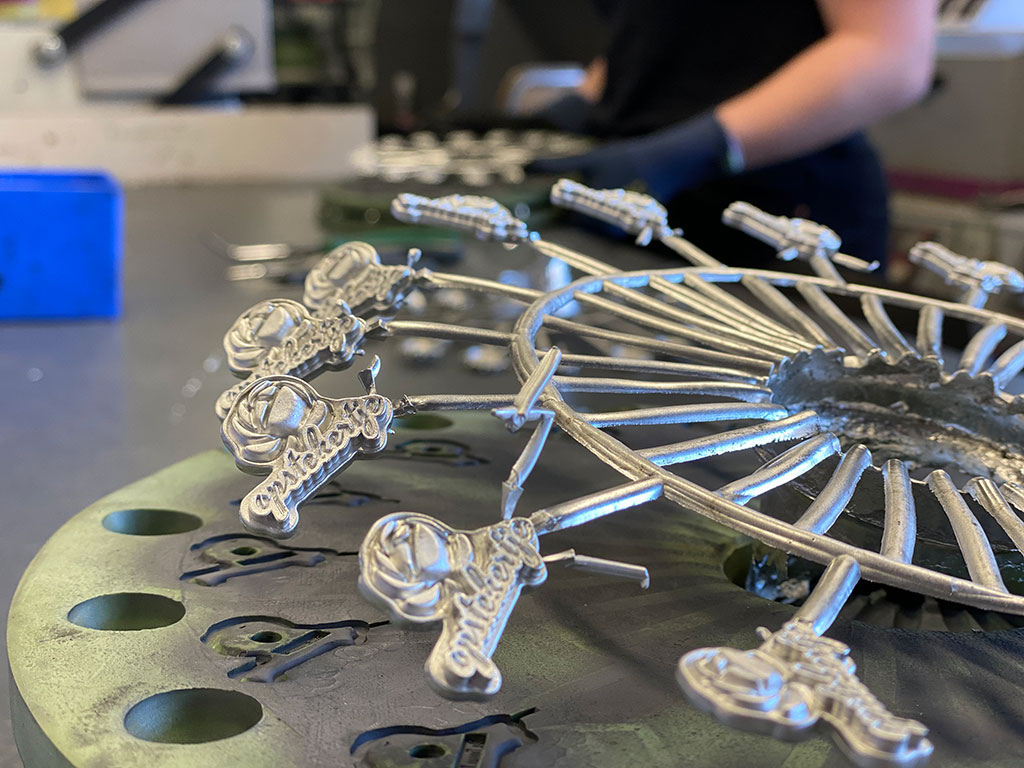

All metal productions are done with us by means of centrifugal casting.

Casting in plastic

Thermoplastic resin is a plastic in the form of a granulate. The granulate becomes liquid by heating and is therefore suitable for casting. In our SiOCAST injection molding machine, the liquid granulate is injected into silicone molds.

All plastic productions are done with us by injection molding.

Reasons for production in thermoplastic resin

Supplier

The weight of the miniatures is less than that of metal ones. The shipping weight is therefore lower and cheaper. There is no difference in quality in the detailing.

Consumer

Some of the players of games, in which miniatures are used, prefer to play with plastic figures. They find this easier to paint or prefer the weight.

Reproduction

What is a reproduction?

With a reproduction you make a copy of existing products. We can cast copies in various materials. We make a new mold of the delivered model with which we can make a single copy or an edition of your choice.

Retouch or new model?

When making a reproduction you may encounter some problems that we would like to solve for you. For example, the original objects may contain damage that needs to be touched up. A mold takes over the object one by one, so also with the irregularities. Not all objects are released. That is, they cannot come out of the mold in one section. The solution for this is to have it consist of several cast parts that are assembled during the finishing. In case of excessive damage, it can be considered to make a new model by means of a 3D drawing or modeling work.

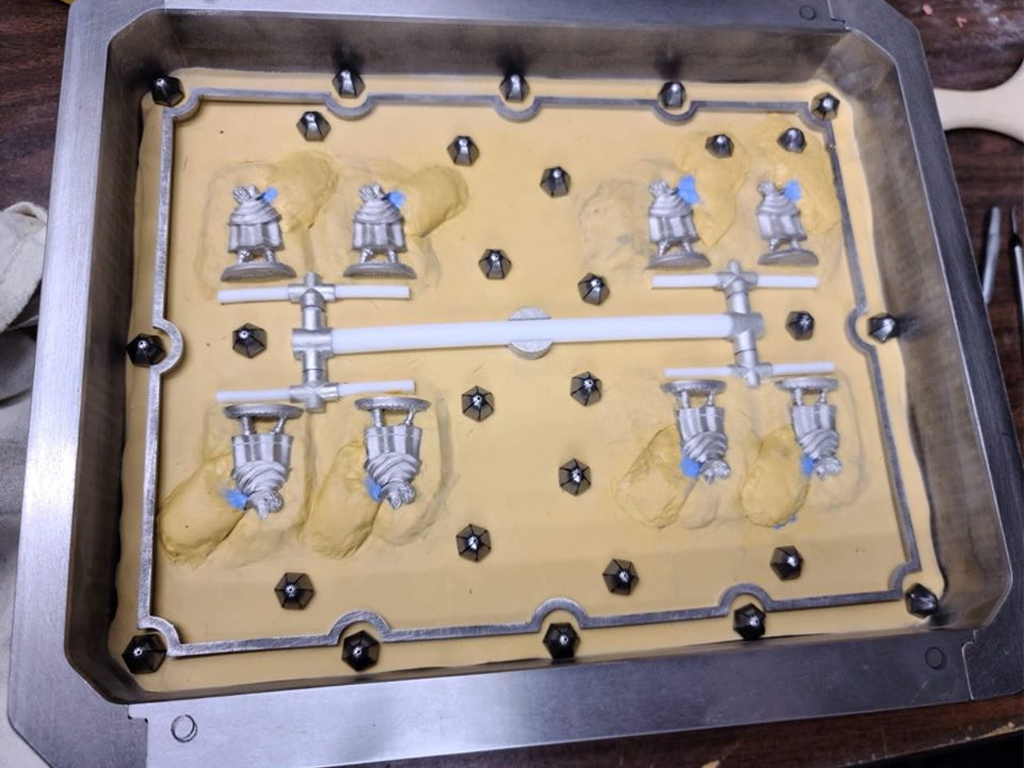

Make mold

We make a casting mold to make a reproduction. For creating a mold we use the original item, a repaired version thereof or a completely new model of it. When making a larger production, we will cast some masters with which we can make a production mold. Multiple items can be cast at the same time with the production mold.

Copyrights

We are bound by copyrights when making new castings and reproductions.

For this reason we are not allowed to (re) produce everything, unless there is an official permission for it.