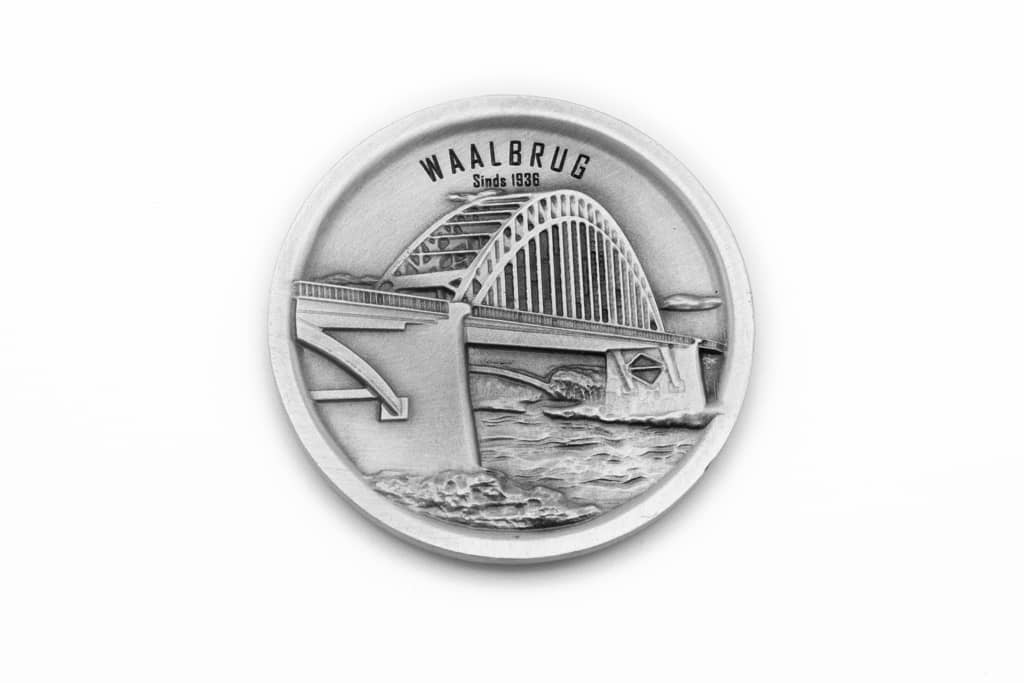

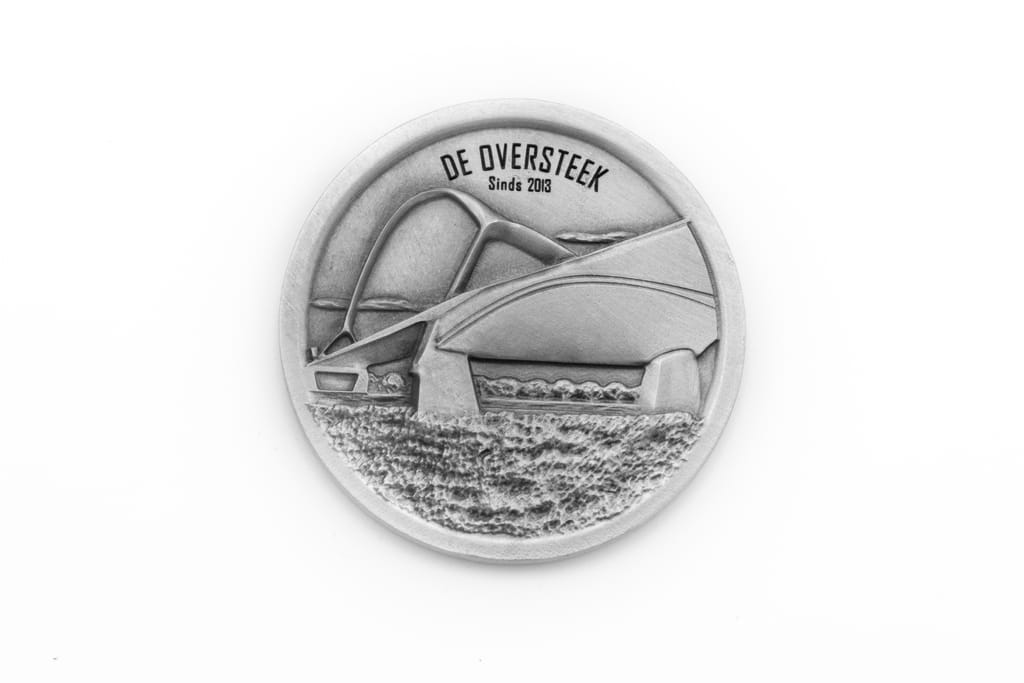

Coin Waalbrug / De Oversteek Nijmegen

Client: De Tinnen Roos

Design: Eduardo Pérez

Format: diameter 50 mm

Material: tin-bismuth alloy

Two bridges

Nijmegen is connected to the rest of the country by two important bridges. The oldest, the Waal Bridge, has been doing this since 1936. At the time, architect G. Schoorl created the longest arch span in Europe. Since then, the bridge has been modified and extended a number of times to bring as much daily traffic to the other side as possible. The many traffic jams and the new district on the other side of the Waal ensured that on November 23, 2013 De Oversteek was taken into use as the second traffic bridge. De Oversteek was designed by architects Laurent Ney and Chris Poulissen.

Both bridges have been portrayed on this coin. They both adorn one side so that they could be drawn with as much detail as possible.

Own souvenir line

This coin was conceived and designed in-house to expand our range of local souvenirs. With a wide range of Four Days Marches souvenirs in our assortment, we chose to also release some more neutral souvenirs related to the oldest city in the Netherlands.

What our clients say

Planning to create a commemorative coin?

Do you have a special moment that you want to capture in a unique way? De Tinnen Roos thinks along with you in the design and manufacture of a commemorative coin. Suitable as a gift to special people, but also for private sale as a souvenir. Please feel free to contact us for the possibilities and a quotation.

We’ve been producing unique and beautiful coins for a large variety of clients

Techniques

Design and model

Design on the computer

Two different 3D design programs were used to design this coin. In the first step, a solid base object with the correct dimensions was created in SolidWorks. This drawing program is suitable for technical drawings. The basic figure has been imported into ZBrush in which you can “clay” more on your screen. In this program the different characters and texts were created to be minted. By looking at the design from a different angle each time in the program, as many details as possible could be added and we knew in advance how these would turn out in the actual currency.

Milling

The design was sent by the computer to our milling machine. The plastic was removed layer by layer from a piece of plastic. During this process, the details became more and more visible. After everything had been milled out, the plastic coin was cleaned so that there was no leftover sharps and other dirt on it. Ready for the first casting to make masters.

Casting and finishing

Making mold and casting

The masters were cast in a first mold using the plastic coin. Masters are used to make the production mold. All molds are manufactured in-house and adapted per product for the best casting results. We had room for eleven copies in the mold of this coin. So we could produce eleven coins per casting round. It is cast with a tin-bismuth alloy. This alloy is produced by ourselves in the casting pots. With each pour, the mixture is manually poured into the spincasting machine.

Finishing with acids

After cutting and edging the cast coin, the product is not yet ready. The coin then still has the dull silver color of the material itself. To get the antique look of our endproduct, the commemorative coin has been given an acid bath. The entire surface was carefully made free of grease and dust before the acid was added. The smallest details were cleaned with a toothbrush so that no spots were missed. Finally, the coin is brushed clean to polish away the dark layer and give the coin its final appearance.